Sustainability in mRNA Raw Materials: Eco-Friendly Options and Practices

In recent years, mRNA technology has emerged as a groundbreaking tool in biotechnology and medicine, especially evident through its role in vaccine development. However, the production of mRNA involves a range of raw materials and processes that can impact the environment. As the demand for mRNA-based solutions grows, so does the need for sustainable practices in its production.

Environmental Footprint of mRNA Production

The environmental footprint of mRNA production primarily stems from the raw materials used and the energy required for the synthesis processes. mRNA production involves the use of nucleotides, enzymes, and various chemical reagents, many of which are derived from non-renewable resources. Additionally, the production process often requires significant amounts of energy, which can contribute to greenhouse gas emissions if sourced from fossil fuels.

Another concern is the generation of chemical waste and by-products, which need to be managed to minimize their environmental impact. The manufacturing facilities also contribute to the overall footprint through their operational practices, including energy consumption, water usage, and waste management.

Eco-Friendly Alternatives for mRNA Raw Materials

The quest for sustainable mRNA production involves an effort to identify and implement eco-friendly alternatives for raw materials. Several innovative approaches are making strides toward reducing the environmental impact of mRNA manufacturing:

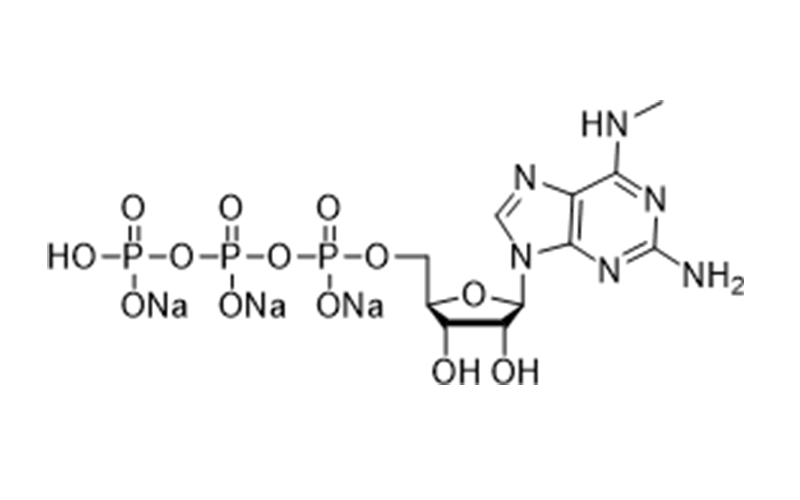

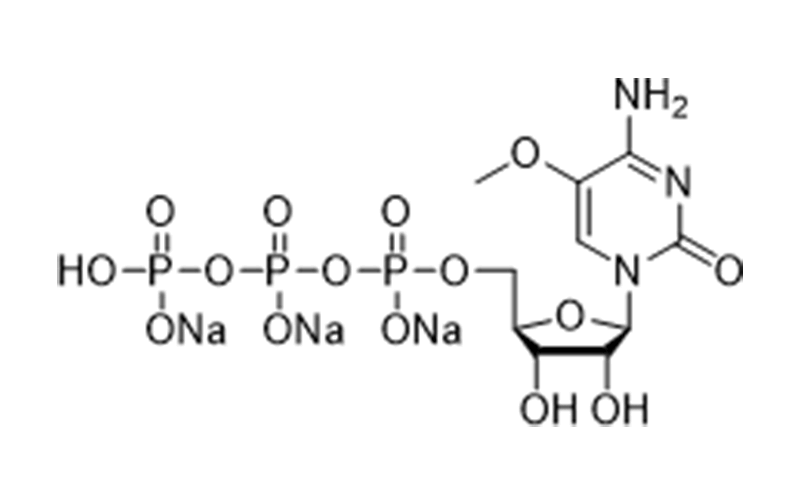

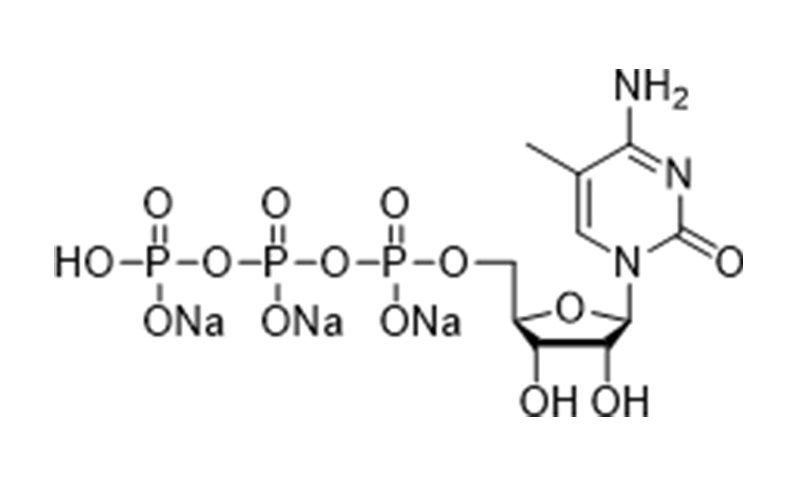

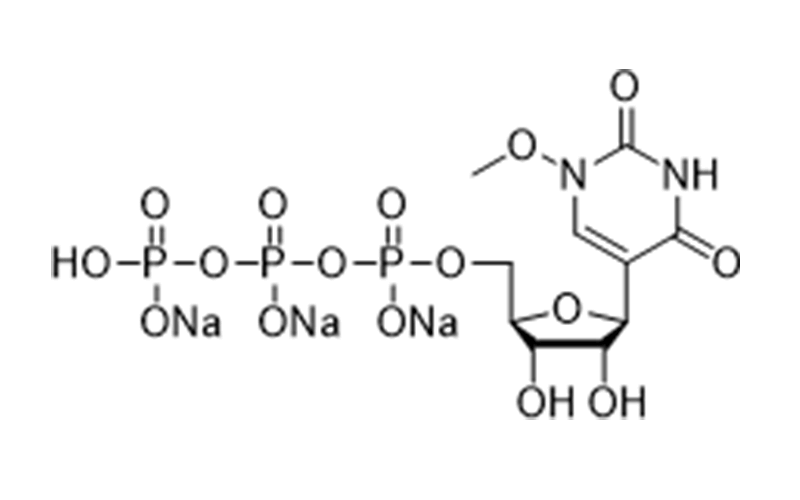

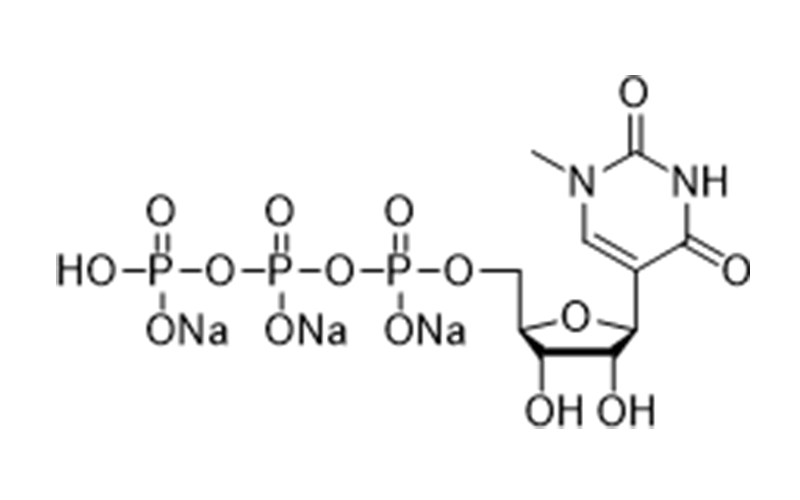

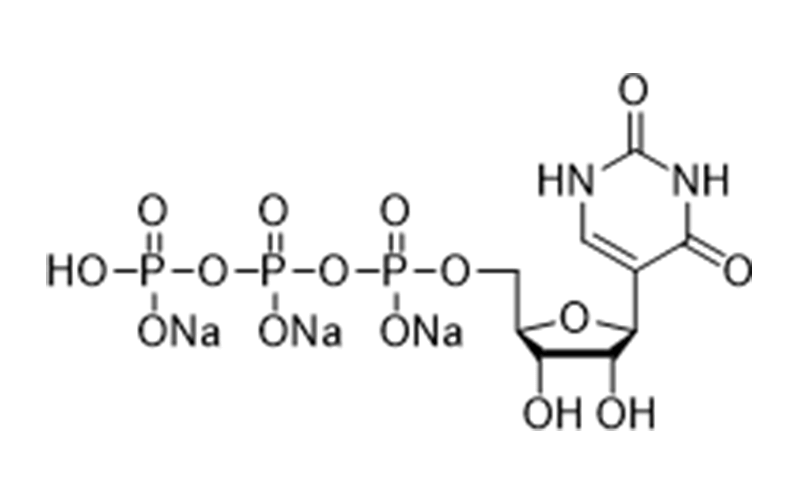

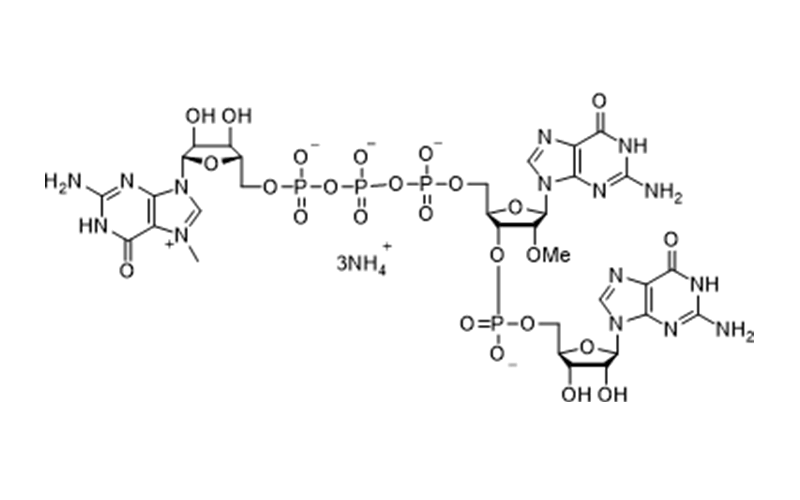

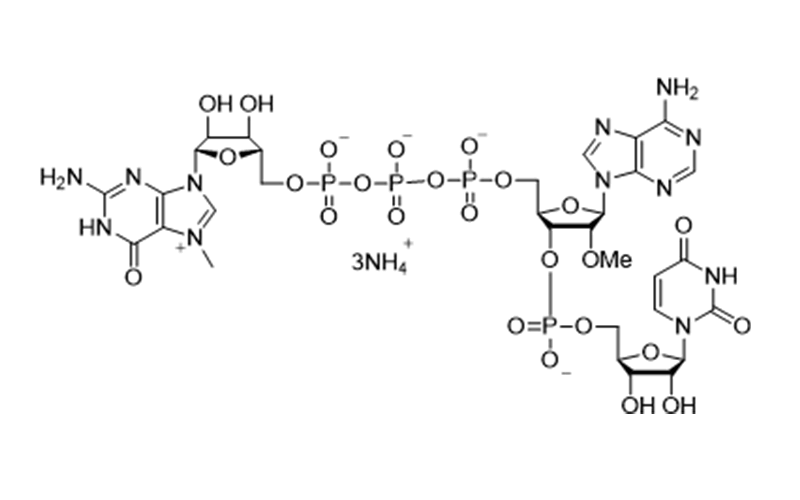

- Bio-Based Nucleotides: Traditional nucleotides used in mRNA synthesis are often derived from non-renewable sources. However, researchers are exploring bio-based alternatives produced from renewable biomass. These bio-based nucleotides are synthesized using biological processes, such as fermentation, which utilize plant or microbial sources instead of fossil fuels. By shifting to these renewable sources, the dependence on petrochemical-derived nucleotides can be significantly reduced, leading to a lower carbon footprint.

- Green Chemistry Innovations: The principles of green chemistry aim to design chemical processes that minimize the use of hazardous substances and reduce environmental impact. In the context of mRNA production, this means developing cleaner synthesis methods that require fewer toxic reagents and generate less waste. For example, using water as a solvent instead of organic solvents can decrease the environmental impact of the synthesis process. Additionally, researchers are working on more efficient enzyme catalysts that can operate under milder conditions, further reducing energy consumption and waste.

- Recycling and Recovery Systems: Implementing systems to recycle and recover reagents and solvents used in mRNA production can significantly cut down on the need for new raw materials. Advances in recovery technologies enable the reuse of valuable materials, such as solvents and enzymes, reducing both waste and costs. For instance, solvent recovery systems can purify and recycle solvents used in the purification stages of mRNA production, minimizing environmental contamination and resource depletion.

- Alternative Chemical Reagents: Another area of focus is the development of alternative chemical reagents that are less harmful to the environment. For example, replacing hazardous chemical reagents with less toxic or biodegradable options can help in reducing the overall environmental impact of the production process.

By applying these environmentally friendly alternatives to mRNA production, the biotechnology industry can move towards a more sustainable direction. These innovations not only help reduce environmental impact, but also contribute to more environmentally friendly and responsible advances in biotechnology.

Sustainable Practices in mRNA Production

As the biotechnological landscape evolves, integrating sustainability into mRNA production has become a priority. Sustainable practices in mRNA production are multifaceted, addressing energy consumption, waste management, process optimization, and adherence to environmental standards. Here’s a deeper look into these key areas:

Energy Efficiency

Energy consumption is a significant factor in the environmental footprint of mRNA production. Traditional mRNA synthesis processes can be energy-intensive, often relying on non-renewable sources of power. To counteract this, many production facilities are turning to renewable energy sources such as solar, wind, and hydroelectric power. By transitioning to these greener alternatives, facilities can substantially reduce their carbon footprint.

Moreover, implementing energy-efficient technologies within production facilities is crucial. Upgrading to high-efficiency equipment, such as advanced cooling systems and energy-saving lighting, can further decrease energy consumption. Heat recovery systems, which capture and reuse waste heat from manufacturing processes, also contribute to reduced energy needs and operational costs.

Waste Management

Effective waste management is essential to minimizing the environmental impact of mRNA production. The production process generates chemical waste, by-products, and spent solvents, which need careful handling. Implementing comprehensive waste management strategies can help mitigate these impacts:

- Recycling and Reuse: Developing systems for recycling and reusing chemicals and solvents can significantly reduce waste. For example, solvent recovery units can purify and reuse solvents, minimizing the need for fresh supplies and reducing chemical disposal requirements.

- Advanced Waste Treatment: Technologies such as advanced oxidation processes and membrane filtration can treat and neutralize hazardous waste, ensuring that it is safely processed or disposed of. This helps to prevent pollution and reduces the risk of environmental contamination.

Process Optimization

Optimizing production processes is key to enhancing sustainability. Innovations in process design and technology can lead to more efficient use of resources and reduced waste. Several approaches can be employed:

- Efficient Reactors: Upgrading to more efficient reactors can improve reaction yields and reduce the amount of raw materials needed. This leads to lower overall resource consumption and less waste generation.

- Improved Purification Techniques: Advanced purification methods, such as high-performance liquid chromatography (HPLC), can enhance the efficiency of separating mRNA products from impurities. This reduces the need for excessive amounts of reagents and solvents, contributing to a lower environmental footprint.

- Continuous Manufacturing: Adopting continuous manufacturing processes instead of batch production can streamline operations and reduce resource use. Continuous systems often operate more efficiently and produce less waste compared to traditional batch methods.

Certification and Standards

Adhering to environmental standards and obtaining certifications is crucial for ensuring that mRNA production processes meet sustainability criteria. Certifications such as ISO 14001, which focuses on effective environmental management systems, help production facilities demonstrate their commitment to environmental stewardship.

In addition to formal certifications, adopting industry best practices and participating in environmental initiatives can enhance the sustainability profile of mRNA production. Collaboration with organizations and regulatory bodies to develop and implement guidelines for sustainable practices ensures that the industry remains aligned with environmental goals.

Integrating Sustainability into mRNA Production

Integrating these sustainable practices into mRNA production requires collaborative efforts involving various departments, including technology developers, regulatory agencies, and production facilities. By prioritizing energy efficiency, effective waste management, process optimization, and compliance with environmental standards, the mRNA industry can significantly reduce its impact on the environment and contribute to a more sustainable future.

With the continuous advancement of technology and the emergence of new technologies, there is enormous potential for further improvement in sustainability. Continuous research, investment, and innovation will play a crucial role in driving these advances and ensuring that mRNA production is both efficient and environmentally responsible.

Challenges and Solutions in Sustainable mRNA Production

Transitioning to sustainable mRNA production presents significant hurdles. A primary challenge is the economic viability of eco-friendly alternatives. Developing and implementing sustainable processes often requires substantial upfront investments in research, development, and new infrastructure. Additionally, the cost of raw materials from renewable sources can be higher compared to traditional, petroleum-based options.

Another obstacle is the scalability of sustainable production methods. While laboratory-scale experiments may demonstrate the feasibility of eco-friendly approaches, scaling these processes to meet the demands of large-scale mRNA production can be complex and time-consuming. Ensuring consistent quality and yield while minimizing environmental impact requires careful optimization and engineering.

Qingmu Pharmaceutical as a mRNA Material Manufacturer

The sustainability of mRNA production is crucial for advancing this revolutionary technology while reducing its impact on the environment. Key practices such as improving energy efficiency, strengthening waste management, optimizing processes, and complying with environmental standards are crucial for achieving a greener future.

Qingmu, a leading mRNA material manufacturer, is a prominent example of the field’s commitment to sustainable development. Aoki excels in integrating environmental practices, from using renewable energy and energy-saving technologies to adopting advanced waste management and recycling methods. The company also focuses on procuring sustainable raw materials and strengthening its commitment to environmental responsibility.

With the development of mRNA technology, the industry’s shift towards sustainable practices will be particularly important. Qingmu’s efforts highlight how to balance technological progress and environmental management, setting an industry benchmark.

For more information about Qinmgu, please contact our sales team.