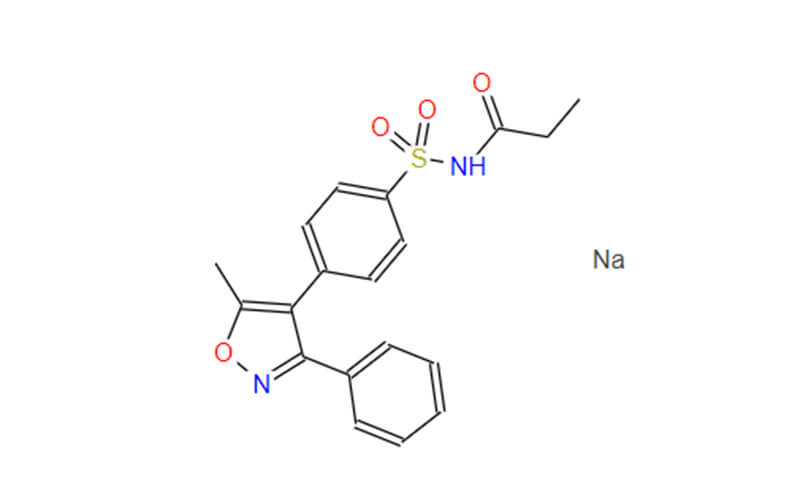

Quality Control in Parecoxib Sodium API Production: Best Practices and Standards

In the pharmaceutical industry, ensuring the highest quality standards in drug production is paramount. One such drug, Parecoxib Sodium, used as an analgesic and anti-inflammatory agent, requires stringent quality control measures during its Active Pharmaceutical Ingredient (API) production. This article delves into the best practices and standards in quality control for Parecoxib Sodium API production, ensuring the delivery of safe and effective medication to patients.

Understanding Quality Control in Parecoxib Sodium Production

Ensuring high-quality production of Parecoxib Sodium, a non-steroidal anti-inflammatory drug (NSAID), involves implementing rigorous quality control (QC) measures at every stage of the manufacturing process. QC in pharmaceutical production is a multi-faceted approach that requires attention to detail, adherence to regulatory standards, and the use of advanced analytical techniques.

Definition and Purpose of Quality Control

Quality control (QC) is the set of procedures employed to ensure that a product adheres to a defined set of quality criteria and meets the requirements of the end-user or customer. In the pharmaceutical industry, QC is critical because it directly impacts patient safety, product efficacy, and regulatory compliance. The primary goals of QC in Parecoxib Sodium API production are to:

- Ensure Consistency: Consistent quality in every batch of Parecoxib Sodium is essential to ensure that each dose administered to patients is safe and effective.

- Maintain Purity and Potency: Ensuring that the API is free from contaminants and that it meets the specified potency requirements is crucial for therapeutic effectiveness.

- Comply with Regulations: Adhering to international and local regulatory standards, such as those set by the FDA, EMA, and other bodies, is mandatory for legal compliance and market approval.

- Guarantee Safety: Protecting patient health by preventing harmful impurities and ensuring the API’s stability and shelf life is important.

Key Quality Control Measures in Parecoxib Sodium Production

Stringent quality control measures are woven throughout the entire Parecoxib Sodium production process, from start to finish. Here’s a deeper dive into these critical steps:

1. Starting Material Testing

Raw materials like starting chemicals and solvents undergo a battery of tests before being accepted for production. These tests typically include:

- Identity: Techniques like spectroscopy confirm the raw material is exactly what it claims to be, preventing accidental use of incorrect chemicals.

- Purity: Assays quantify the amount of the desired material present, ensuring minimal levels of impurities that could affect the final product.

- Moisture Content: Excessive moisture can impact chemical reactions and product stability. Tests determine moisture levels to ensure they fall within acceptable limits.

- Heavy Metals: Trace amounts of heavy metals like lead, mercury, or arsenic can be toxic. Testing ensures these are within the strict limits set by regulatory bodies.

2. In-Process Control

Throughout the multi-step synthesis of Parecoxib Sodium, samples are extracted at specific points. These samples undergo various analyses to monitor the reaction progress and identify any deviations:

- pH Monitoring: Maintaining the correct reaction medium (acidic, basic, or neutral) is crucial for efficient synthesis. Regular pH measurement ensures the reaction stays on track.

- Yield Determination: Yield refers to the amount of final product obtained. Monitoring yield at various stages helps identify potential issues that might be reducing the final quantity of Parecoxib Sodium.

- Impurity Profiling: While the focus is on the desired product, identifying and quantifying any impurities formed during the reaction allows for adjustments to minimize their presence in the final product.

3. Final Product Testing

Once the synthesis is complete, the Parecoxib Sodium undergoes a comprehensive testing battery to confirm it meets all pre-defined specifications:

- Identity Testing: Techniques like X-ray diffraction or infrared spectroscopy definitively confirm the material is Parecoxib Sodium and not a byproduct or contaminant.

- Assay: This test precisely determines the amount of pure Parecoxib Sodium present in the final product, ensuring it meets the specified potency for effective pain relief.

- Residual Solvents: Some solvents might be used during the synthesis. Testing ensures any residual solvent levels fall below established safety limits.

- Particle Size Analysis: The size and distribution of Parecoxib Sodium particles can impact how it dissolves and ultimately performs in the body. This analysis ensures consistent particle characteristics for reliable drug formulation.

- Microbiological Testing: The final product is tested for the absence of bacteria or fungi that could pose a health risk.

4. Documentation

Every step of the production process is meticulously documented. This includes:

- Certificates of Analysis (COA) for Starting Materials: These documents from suppliers detail the test results performed on the raw materials.

- Batch Production Records: These detailed logs record all activities performed during each production batch, including equipment used, reaction times, and observations made.

- Final Product Certificates of Analysis (COA): These reports summarize the results of all tests performed on the finished Parecoxib Sodium, demonstrating its compliance with quality standards.

This meticulous documentation creates a traceable record. If any issues arise downstream, these records allow for a thorough investigation to pinpoint the root cause and prevent similar occurrences in future batches.

Best Practices in Quality Control for Parecoxib Sodium

Implementing best practices in QC for Parecoxib Sodium production involves adopting a holistic approach that encompasses all aspects of the production process. Key best practices include:

- Strict Adherence to Good Manufacturing Practices (GMP): Following GMP guidelines ensures that all processes and procedures meet the highest standards of quality and consistency.

- Comprehensive Training Programs: Regular training for personnel involved in the production and quality control processes ensures they are well-versed in the latest techniques and regulatory requirements.

- Robust Documentation and Record-Keeping: Maintaining detailed records of all QC activities, from raw material testing to final product release, provides traceability and accountability.

- Regular Audits and Inspections: Conducting periodic internal and external audits helps in identifying potential areas of improvement and ensures compliance with regulatory standards.

- Advanced Analytical Techniques: Utilizing state-of-the-art analytical methods for testing and validation enhances the accuracy and reliability of QC results.

Challenges in Quality Control and How to Overcome Them

| Challenge | Description | Solutions |

| Complex Synthesis Process | The intricate, multi-step synthesis of Parecoxib Sodium can lead to product variability. | Real-Time Monitoring: Implement automated systems to monitor and control critical parameters like temperature and pH. Standard Operating Procedures (SOPs): Develop and adhere to detailed SOPs for each synthesis step. Process Validation: Conduct thorough validation studies to understand and control critical aspects of the process. |

| Detection of Impurities | Impurities from raw materials and by-products can compromise product quality. | Advanced Purification Techniques: Employ methods such as high-performance liquid chromatography (HPLC) and recrystallization. Sensitive Analytical Methods: Utilize techniques like mass spectrometry (MS) and nuclear magnetic resonance (NMR) spectroscopy. Regular Monitoring: Implement routine checks at various stages of production to detect and address impurities early. |

| Regulatory Compliance | Varying and evolving pharmaceutical regulations pose compliance challenges. | Continuous Training: Regularly update staff on current Good Manufacturing Practices (cGMP) and regulatory changes. Regulatory Affairs Team: Have a dedicated team to monitor, interpret, and ensure compliance with regulatory standards. Comprehensive Documentation: Maintain detailed records of all QC activities to demonstrate compliance during regulatory inspections. |

| Supply Chain Management | Variability in raw material quality from different suppliers can impact product consistency. | Supplier Qualification: Implement a rigorous process to assess and select reliable suppliers. Regular Audits: Conduct frequent audits to ensure ongoing compliance with quality standards. Strategic Sourcing: Develop relationships with multiple qualified suppliers to mitigate supply risks. |

| Environmental and Occupational Safety | Handling hazardous chemicals and managing waste are critical for safety and environmental protection. | Safety Protocols: Establish strict safety procedures and provide regular training for staff on handling hazardous materials. Personal Protective Equipment (PPE): Ensure the availability and use of appropriate PPE for all employees. Waste Management Systems: Implement effective systems to manage and dispose of chemical waste responsibly. |

By addressing these challenges with advanced techniques, continuous improvement, and adherence to best practices, manufacturers can ensure the high quality of Parecoxib Sodium API, maintaining regulatory compliance and safeguarding patient health.

Conclusion

Maintaining robust quality control in Parecoxib Sodium production is vital to ensure the safety and efficacy of medications containing this API. By adhering to best practices and overcoming challenges, manufacturers can guarantee patients receive the highest quality medication. This, in turn, fosters trust in the pharmaceutical industry and protects public health.

If you have any needs for Parecoxib Sodium API, Qingmu will be your best partner.