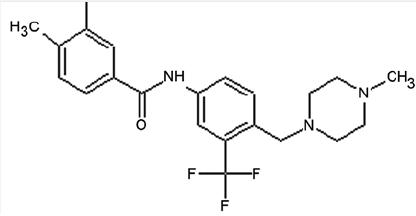

Pharmaceutical Compositions and Process of Ponatinib HCl API

Ponatinib hydrochloride (Ponatinib HCl), also known as AP24534, is a potent tyrosine kinase inhibitor (TKI) used in the treatment of various hematological malignancies, including chronic myeloid leukemia (CML), acute lymphoblastic leukemia (ALL), and various other leukemias and lymphomas. This article delves into the key properties, formulations, pharmaceutical compositions, and manufacturing processes of Ponatinib HCl API (Active Pharmaceutical Ingredient).

Properties of Ponatinib HCl API

Ponatinib hydrochloride (Ponatinib HCl) API, a crucial component in the treatment of various blood cancers, possesses several key properties that influence its formulation, administration, and overall effectiveness. Here’s a closer look at some critical aspects:

1. Physical Properties

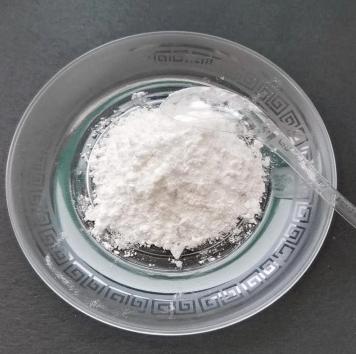

- Appearance: Ponatinib HCl API typically appears as a white to off-white crystalline powder. This crystalline form allows for easier handling and storage during the manufacturing process.

- Melting point: With a melting point of approximately 250°C (482°F), Ponatinib HCl exhibits high thermal stability, crucial for maintaining product integrity during various stages of manufacturing and storage.

- Solubility: Understanding the solubility profile of an API is essential for formulating it into suitable dosage forms. Ponatinib HCl exhibits:

- Sparing solubility in water: This low water solubility presents a challenge for direct aqueous administration. Pharmaceutical formulations must address this limitation to ensure proper absorption by the body.

- Readily soluble in organic solvents: Solvents like dimethylformamide (DMF) and methanol play a role in the manufacturing process of Ponatinib HCl due to its good solubility in these organic media.

2. Chemical Properties

- Molecular Weight: Ponatinib HCl has a molecular weight of 584.74 g/mol. This information is crucial for various aspects, including:

- Dosage calculation: Determining the appropriate amount of API needed for specific dosage strengths in tablets or capsules.

- Understanding potential interactions: Understanding the molecular weight can help predict potential interactions with other molecules in the body or formulation components.

- pKa (acid dissociation constant): This value indicates the acidity or alkalinity of a molecule. Understanding the pKa of Ponatinib HCl is important for:

- Formulating stable and effective dosage forms: By influencing solubility and ionization behavior, pKa can impact formulation development and stability.

- Optimizing drug delivery: Depending on the pKa, specific strategies might be employed to ensure optimal drug absorption and distribution in the body.

3. Other Important Properties

- Hygroscopicity: This refers to a substance’s ability to absorb moisture from the surrounding environment. Ponatinib HCl is not hygroscopic, meaning it doesn’t readily absorb moisture, which simplifies storage and handling during manufacturing and post-manufacturing stages.

- Stability: Maintaining the stability of Ponatinib HCl throughout its lifecycle is critical. While the specific details of its stability profile are commercially confidential, understanding its stability under various conditions (e.g., temperature, light, humidity) is crucial for:

- Ensuring product quality: Ensuring the API maintains its potency and purity throughout its shelf life.

- Developing appropriate storage and handling recommendations: Establishing proper guidelines for pharmacists, healthcare providers, and patients to maintain the product’s integrity.

By understanding these key properties, pharmaceutical scientists and formulators can develop effective and stable formulations of Ponatinib HCl API, ensuring the safe and efficient delivery of this crucial medication to patients in need.

Formulations of Ponatinib HCl API

While Ponatinib tablets and capsules are the most common formulations of Ponatinib HCl API, ongoing research and development efforts are exploring alternative formulations to potentially address specific patient needs and improve therapeutic outcomes. Here’s a deeper look at these potential advancements:

1. Liquid Formulations

- Oral solutions or suspensions: These formulations could be beneficial for patients who have difficulty swallowing tablets or capsules, such as young children, elderly individuals, or those with dysphagia (swallowing difficulties).

- Challenges: Developing stable and palatable liquid formulations for Ponatinib HCl can be challenging due to its poor water solubility. Researchers are exploring the use of solubility-enhancing excipients and novel formulation techniques to overcome these challenges.

2. Novel Delivery Systems

- Controlled release formulations: These formulations aim to release the API gradually over a prolonged period, potentially reducing the frequency of dosing and improving patient compliance.

- Examples: Techniques like matrix tablets, film-coated tablets, and osmotic pumps can be employed to achieve controlled release profiles. This could be beneficial for drugs like Ponatinib HCl with short half-lives, requiring frequent dosing for optimal therapeutic effect.

- Targeted drug delivery systems: These systems aim to deliver the API specifically to cancer cells, potentially reducing systemic exposure and minimizing side effects in healthy tissues.

- Challenges: Developing and implementing targeted delivery systems for Ponatinib HCl is complex and requires extensive research and development efforts. However, the potential benefits of reduced side effects and improved efficacy make this area of research promising.

3. Combination Formulations

- Combining Ponatinib HCl with other targeted therapies: Combining Ponatinib HCl with other drugs targeting different aspects of cancer cell growth or survival might offer synergistic effects, potentially leading to improved treatment outcomes.

- Challenges: Careful consideration of compatibility, dosing regimens, and potential drug interactions is crucial when developing combination formulations.

4. Personalized Medicine Approaches

- Tailoring formulations to individual patient characteristics: Future advancements might involve tailoring the dosage form, release profile, or even the API itself to individual patient needs and genetic profiles. This personalized approach could potentially optimize treatment efficacy and minimize side effects for specific patient populations.

It is important to note that these potential formulations are still under research and development, and their availability and effectiveness require further clinical evaluation and regulatory approval. However, these advancements showcase the ongoing efforts to improve the therapeutic potential of Ponatinib HCl by exploring diverse formulation options beyond traditional tablets and capsules.

Pharmaceutical Compositions of Ponatinib HCl API

Understanding the intricacies of pharmaceutical compositions for Ponatinib HCl API goes beyond simply listing excipients. Here’s a closer look at the key components and considerations involved:

1. Selection of Excipients

Choosing the right excipients plays a critical role in the success of a Ponatinib HCl formulation. Here are some specific considerations:

- Compatibility: Each excipient must be compatible with both the API and other excipients in the formulation. This ensures stability and prevents interactions that could affect the drug’s efficacy or safety.

- Functionality: Each excipient must fulfill its intended function effectively. For example, binders need to hold the tablet together, while disintegrants need to facilitate rapid disintegration in the stomach.

- Regulatory compliance: All excipients used must meet relevant regulatory requirements and be of pharmaceutical grade to ensure patient safety.

Common excipients used in Ponatinib HCl formulations and their specific functionalities include:

- Binders: Polyvinylpyrrolidone (PVP), hydroxypropyl methylcellulose (HPMC) – Promote tablet or capsule formation by binding the API and other excipients together.

- Fillers: Microcrystalline cellulose, lactose monohydrate – Dilute the API to achieve the desired dosage form and tablet size.

- Disintegrants: Sodium starch glycolate, croscarmellose sodium – Facilitate rapid disintegration of the tablet or capsule in the stomach, allowing for quicker release of the API.

- Lubricants: Magnesium stearate, stearic acid – Prevent sticking of the API and excipients during manufacturing and ensure smooth passage of tablets or capsules through the digestive system.

- Glidants: Colloidal silicon dioxide – Improve flowability of the powder blend during manufacturing.

- Anti-caking agents: Silicon dioxide – Prevent caking and clumping of the powder blend, ensuring consistent dosage accuracy.

- Film coating: Hypromellose, hydroxypropyl cellulose – Provide various benefits, including protecting the API from moisture and light, regulating the release profile of the drug, and masking bitter taste.

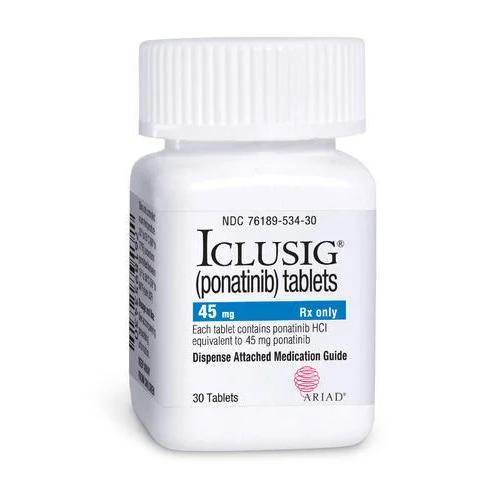

2. Dosage Strength

Ponatinib HCl tablets and capsules are typically available in various dosage strengths, ranging from 15 mg to 180 mg. This allows for individualized treatment plans based on factors like patient body weight, disease severity, and potential side effects.

3. Controlled Release

Ponatinib HCl has a relatively short half-life, meaning its concentration in the body diminishes rapidly. To address this, formulations might employ controlled release strategies to achieve a more sustained release profile. This can be achieved through:

- Film coating: Applying a specific film coating to the tablet can delay the release of the API, allowing for gradual absorption into the bloodstream over a longer period.

- Matrix formulation: Formulating the API within a matrix of specific excipients can create a sustained release effect by controlling the rate of drug diffusion from the matrix.

4. Optimization and Testing

Developing an effective and safe pharmaceutical composition involves extensive optimization and testing. This includes:

- Formulation development: Experiment with different excipients and their ratios to achieve the desired release profile, stability, and other characteristics.

- In vitro testing: Conduct laboratory studies to assess the dissolution profile, stability, and compatibility of the formulation.

- In vivo testing: In some cases, conducting clinical trials to evaluate the safety and efficacy of the formulated drug in humans.

Manufacturing Process of Ponatinib HCl API

The manufacturing process of Ponatinib Hydrochloride (HCl) API involves several steps that require careful synthesis and purification to ensure the final product meets stringent quality standards. Here’s an overview of the typical manufacturing process:

1. Raw Material Procurement:

The manufacturing process begins with the procurement of high-quality raw materials, including starting materials, solvents, catalysts, and reagents. Each raw material must meet specified purity and quality requirements to ensure the integrity of the final product.

2. Chemical Synthesis:

- Step 1: Formation of Intermediate Compounds

The synthesis of Ponatinib HCl typically involves multiple intermediate steps, each carefully orchestrated to achieve specific chemical transformations. These intermediates are essential for building the molecular structure of Ponatinib.

- Step 2: Cyclization Reaction

A key step in the synthesis involves a cyclization reaction, where the intermediates are combined under controlled conditions to form the core structure of Ponatinib. This step often requires precise temperature control, catalysts, and reaction times to achieve optimal yields and purity.

- Step 3: Salt Formation

Following the cyclization reaction, the desired product is typically obtained as a salt, such as Ponatinib Hydrochloride (HCl). This salt formation step involves the addition of hydrochloric acid to the reaction mixture to convert the free base form of Ponatinib into its hydrochloride salt, which is more stable and suitable for pharmaceutical use.

3. Purification and Isolation:

Once the desired product is formed, it undergoes purification to remove impurities and by-products generated during the synthesis process. Purification techniques may include crystallization, filtration, chromatography, or recrystallization. These processes help ensure the final API meets strict quality standards for purity and potency.

4. Drying and Solid-State Characterization:

After purification, the Ponatinib HCl API is typically dried to remove residual solvents and moisture. Drying processes may include vacuum drying, freeze-drying, or oven drying, depending on the specific requirements of the API. Solid-state characterization techniques, such as X-ray powder diffraction (XRPD) and differential scanning calorimetry (DSC), may also be used to assess the physical properties and crystal structure of the final product.

5. Quality Control:

Throughout the manufacturing process, rigorous quality control measures are implemented to monitor the purity, potency, and consistency of the Ponatinib HCl API. Analytical techniques such as high-performance liquid chromatography (HPLC), mass spectrometry (MS), and nuclear magnetic resonance (NMR) spectroscopy are employed to verify the identity and purity of the API at various stages of production.

6. Packaging and Storage:

Once the Ponatinib HCl API has passed quality control testing, it is typically packaged in suitable containers and stored under controlled conditions to maintain its stability and integrity. Proper packaging and storage practices help ensure the API retains its efficacy and meets regulatory requirements for pharmaceutical use.

In summary, the manufacturing process of Ponatinib HCl API involves a series of carefully controlled chemical reactions, purification steps, and quality control measures to produce a high-quality pharmaceutical ingredient suitable for use in the treatment of leukemia and other related diseases.

Conclusion

Ponatinib HCl API plays a significant role in the treatment of various hematological malignancies. Understanding its properties, formulations, pharmaceutical compositions, and manufacturing processes is crucial for ensuring the development of safe and effective medications for patients in need. As research and development in this field continue, advancements can lead to improved formulations and manufacturing processes, further optimizing the therapeutic potential of Ponatinib HCl. This is an area that the ponatinib manufacturers have been exploring.

Ponatinib HCl API stands as one of the pivotal products within Qingmu’s manufacturing repertoire. Renowned for its state-of-the-art facilities, Qingmu Pharmaceutical maintains a steadfast commitment to upholding stringent quality standards and regulatory compliance. Leveraging advanced technologies and refined processes, the company guarantees the purity, potency, and uniformity of its APIs. Anchored in a culture of innovation, Qingmu Pharmaceutical diligently pursues research and development initiatives to bolster its manufacturing prowess and diversify its product range, effectively catering to evolving medical demands and unmet needs.

If you are in any interests about our product or service, never hesitate to contact us.