Mitigating Shortages: Strategies for a Stable Supply Chain of Rotigotine API

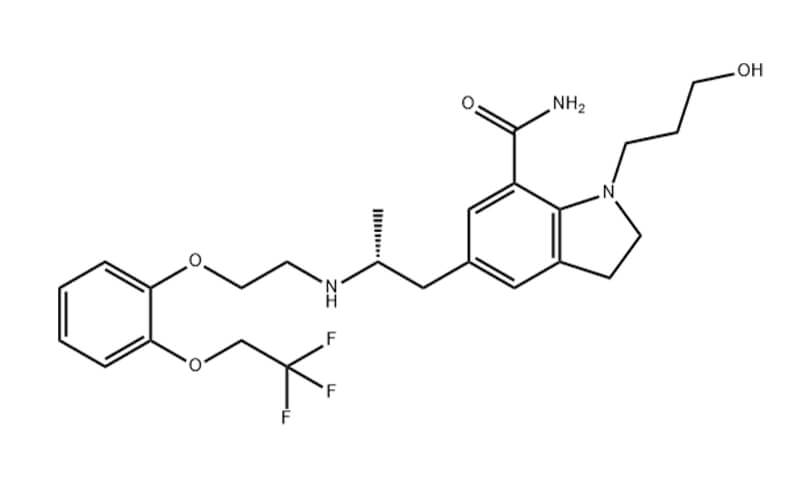

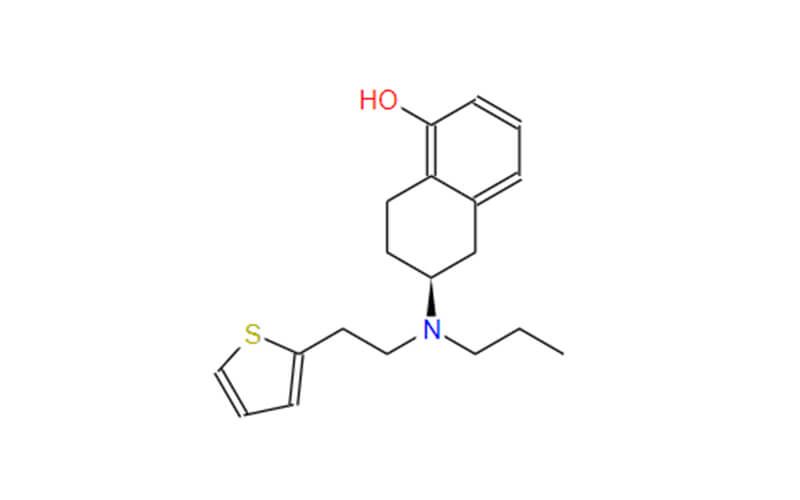

Rotigotine API, a vital ingredient in medications for Parkinson’s disease and restless legs syndrome (RLS), has experienced supply chain disruptions in recent years. These shortages can leave patients struggling to access their medications and healthcare providers facing challenges in maintaining treatment regimens. This article explores the causes of these shortages and offers proactive strategies to ensure a stable supply of Rotigotine API in the future.

What Caused the Shortages of Rotigotine API?

Several factors have conspired to create a volatile supply chain for Rotigotine API, leaving patients and healthcare providers scrambling for this essential medication. Here’s a deeper dive into the root causes:

- Limited Number of Manufacturers: The global production of Rotigotine API is concentrated amongst a select few suppliers. This lack of diversification creates a single point of failure. If a single manufacturing facility experiences issues like a quality control problem, a production shutdown for maintenance, or even a natural disaster, the entire supply chain feels the ripple effects.

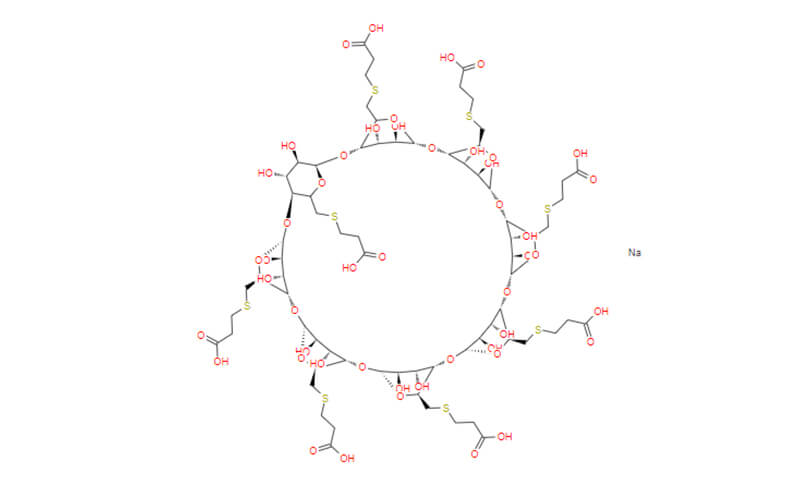

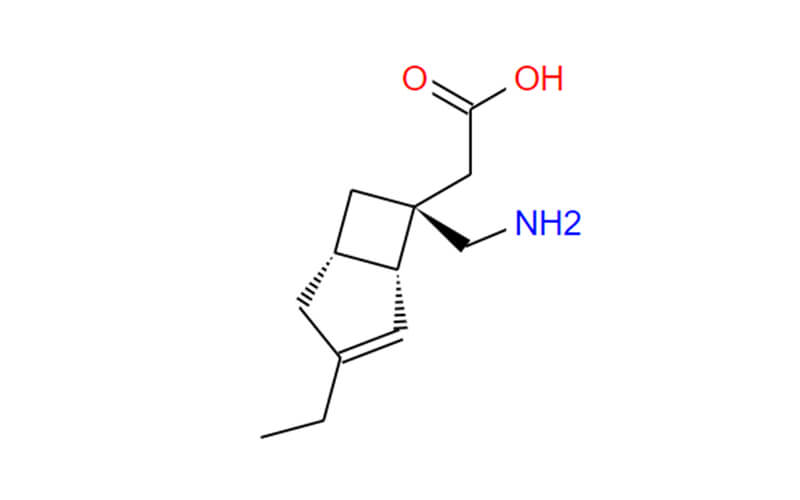

- Complex Manufacturing Process: Manufacturing Rotigotine API is no small feat. It involves a multi-step chemical synthesis process with stringent quality control measures at each stage. Any hiccup during these intricate steps, from sourcing raw materials to final purification, can lead to production delays and shortages.

- Increasing Demand Outpaces Production: The global population is aging, and with it comes a rise in age-related neurological conditions like Parkinson’s disease. Additionally, RLS is gaining greater recognition, leading to more diagnoses and prescriptions for medications containing Rotigotine API. Unfortunately, the production capacity for Rotigotine API hasn’t kept pace with this growing demand, creating a strain on the existing supply.

- Geopolitical and Economic Instability: The globalized nature of the pharmaceutical industry introduces another layer of complexity. Trade tensions, political instability in certain regions, and fluctuations in currency exchange rates can all disrupt the smooth flow of raw materials and finished products, impacting the availability of Rotigotine API.

These factors intertwine to create a fragile supply chain for Rotigotine API. By understanding the root causes, we can implement proactive strategies to build resilience and ensure this vital medication remains accessible to patients who need it.

Proactive Strategies for a Stable Rotigotine API Supply Chain

The recent shortages of Rotigotine API highlight the need for a more proactive approach to managing the supply chain for this critical medication. Here are some expanded strategies that can be implemented:

- Diversification of Suppliers: Moving beyond simply having multiple suppliers, it’s important to establish partnerships with geographically diverse manufacturers. This reduces the risk of disruptions caused by regional issues like natural disasters or political instability. Additionally, consider collaborating with contract manufacturing organizations (CMOs) that can provide surge capacity in times of increased demand.

- Demand Forecasting and Inventory Management: Implementing robust demand forecasting methods can help anticipate future needs and adjust manufacturing output accordingly. Statistical forecasting models can be combined with patient population data and trends in RLS and Parkinson’s diagnoses to create a more accurate picture of future demand. Safety stock protocols should also be established to maintain a buffer of Rotigotine API to address unexpected fluctuations.

- Collaboration Between Manufacturers and Pharmaceutical Companies: Open communication and collaboration are essential for a smooth-running supply chain. Regular dialogue can help identify potential bottlenecks in production early on. Joint investment in research and development of more efficient manufacturing processes for Rotigotine API can also lead to long-term stability. Additionally, collaboration on contingency plans can ensure a coordinated response in case of unforeseen disruptions.

- Government Regulations and Incentives: Governments can play a vital role in promoting a stable supply chain for Rotigotine API. Streamlining regulatory approval processes for new manufacturing facilities and expediting the qualification of new suppliers can help increase production capacity. Financial incentives, such as tax breaks or grants, can be offered to encourage companies to invest in Rotigotine API production. Regulatory bodies can also work with manufacturers to establish quality standards and inspection protocols that ensure consistent production of high-grade Rotigotine API.

By implementing these proactive strategies, all stakeholders involved in the Rotigotine API supply chain can work together to ensure a stable supply of this medication for patients who rely on it to manage their neurological conditions.

How to Choose A Reliable Rotigotine Manufacturer?

Selecting a reliable supplier for Rotigotine API is crucial for ensuring a consistent and high-quality medication for patients. Here are some key factors to consider when making your choice:

- Manufacturing Expertise: Experience is vital. Look for a manufacturer with a long and successful track record of producing Rotigotine API. Their expertise should encompass not just high-volume production but also a commitment to continuous improvement in quality and efficiency. This ensures they can adapt to evolving regulatory requirements and technological advancements.

- Regulatory Compliance: Strict adherence to quality standards and relevant regulatory requirements is non-negotiable. Look for a manufacturer with certifications from recognized bodies like the US Food and Drug Administration (FDA) or the European Medicines Agency (EMA). Regular audits by independent third-party organizations further demonstrate their commitment to quality control.

- Financial Stability: A financially stable manufacturer is less likely to experience disruptions that could impact supply. Their financial strength ensures they can invest in maintaining and upgrading their facilities, as well as securing a reliable supply of raw materials.

- Transparency and Communication: Open communication is key. Choose a supplier that is transparent about their manufacturing processes, quality control measures, and supply chain. They should be proactive in communicating any potential issues or delays, allowing you to plan accordingly. Additionally, look for a manufacturer that readily answers your questions and provides detailed documentation about their Rotigotine API production.

Qingmu stands out as a leading Rotigotine manufacturer, committed to providing a reliable and high-quality product. They possess a proven track record of excellence, with extensive experience in the production of Rotigotine API.

By partnering with a reliable Rotigotine API manufacturer like Qingmu, you can ensure a stable supply of this critical medication for your patients. Qingmu’s dedication to quality, regulatory compliance, and open communication makes them a trusted partner for all your Rotigotine API needs.