Bisoprolol Fumarate: A Vital API in Cardiovascular Care

The human heart, a tireless engine powering our very existence, requires meticulous care. When malfunctions arise, medications become crucial allies in restoring and maintaining health. Bisoprolol, a medication belonging to the beta-blocker class, plays a vital role in this endeavor. Understanding its components, particularly the bisoprolol API (Active Pharmaceutical Ingredient), and the role of bisoprolol manufacturers, is essential for appreciating its therapeutic impact. This article delves into the world of bisoprolol, exploring its functions, production processes, and how it contributes to cardiovascular well-being.

Understanding the Bisoprolol API

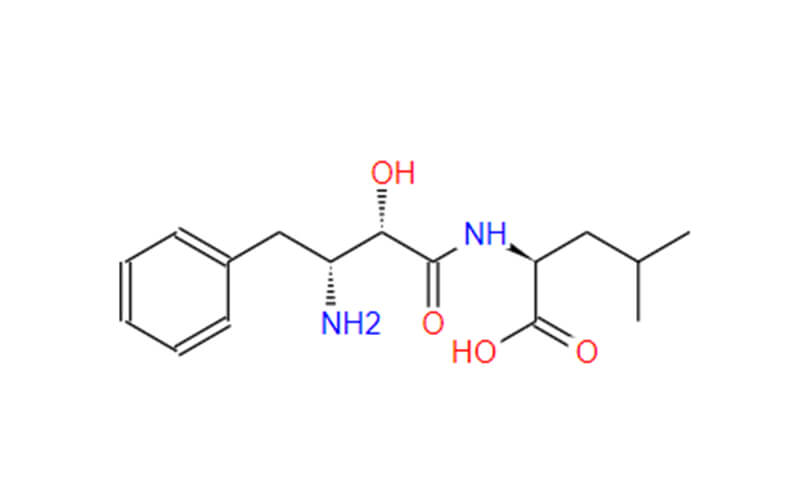

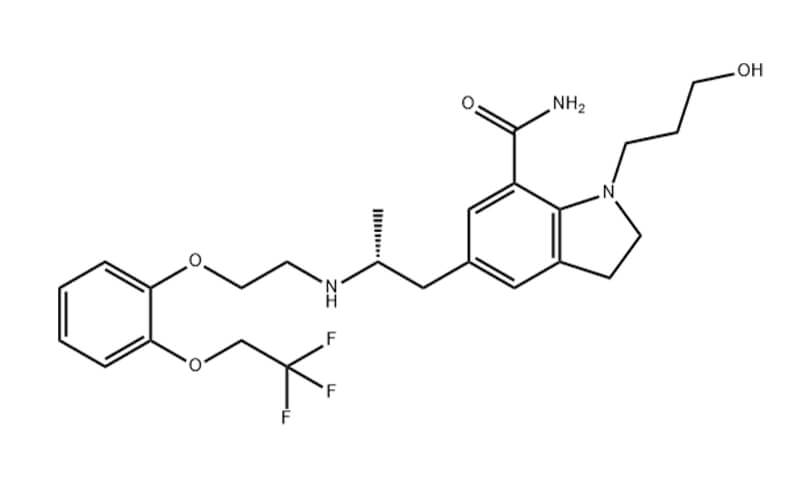

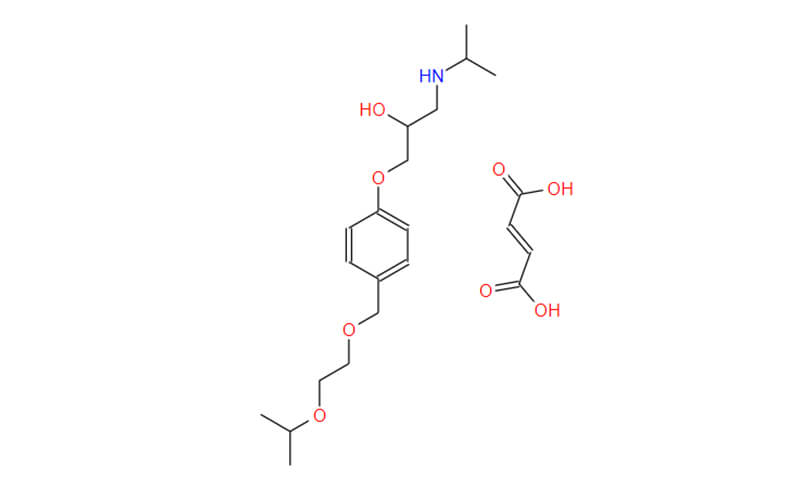

Before diving into the specifics of bisoprolol, let’s establish a crucial fact: medications comprise a blend of various ingredients. The API is the core element responsible for the drug’s intended therapeutic effect. In the case of bisoprolol, the bisoprolol fumarate API is the key player in regulating cardiovascular function.

The production of this API involves a meticulous multi-step process. Raw materials undergo a series of chemical reactions and purifications to yield the pure bisoprolol fumarate. Stringent quality control measures are implemented throughout the process to ensure the API meets the highest safety and efficacy standards.

The Role of Bisoprolol Manufacturers

Identifying reputable bisoprolol manufacturers is paramount. These companies play a critical role in the pharmaceutical supply chain by producing the high-quality bisoprolol API that forms the foundation of bisoprolol medications. They possess the expertise, facilities, and technology to ensure consistent and reliable production that meets regulatory requirements.

Choosing a reliable manufacturer involves considering several factors. A strong track record in quality control, adherence to international standards, and a commitment to ethical practices are all crucial aspects. Additionally, a manufacturer’s experience in API production and their ability to scale up production to meet market demands are important considerations.

Bisoprolol Fumarate Uses: Wide-Ranging Applications in Medicine

Bisoprolol fumarate boasts a wide range of applications in treating various cardiovascular conditions. Here are some prominent uses:

- Hypertension (High Blood Pressure): Bisoprolol fumarate works by selectively blocking beta-1 adrenergic receptors in the heart. This action reduces heart rate and force of contraction, ultimately lowering blood pressure. It is often prescribed alone or in combination with other medications for effective blood pressure control.

- Angina Pectoris (Chest Pain): During angina episodes, the heart muscle doesn’t receive enough oxygen-rich blood. Bisoprolol fumarate helps manage angina by lowering the heart’s workload, thereby reducing its oxygen demand and alleviating chest pain.

- Heart Failure: In heart failure, the heart struggles to pump blood efficiently. Bisoprolol fumarate improves heart function by reducing its workload and improving blood flow. This helps manage symptoms like shortness of breath and fatigue.

Bisoprolol fumarate comes in various dosage forms, including tablets and capsules. The appropriate dosage and route of administration are determined by the healthcare professional based on the individual patient’s needs. Extensive clinical trials have demonstrated the effectiveness of bisoprolol fumarate in treating these conditions.

The Production Process of Bisoprolol Fumarate

The production of bisoprolol fumarate is a multi-stage chemical synthesis process that takes place in controlled environments within specialized manufacturing facilities. Here’s a detailed breakdown of the key steps:

1. Raw Material Acquisition:

The first step involves acquiring the necessary ingredients. These raw materials fall into three main categories:

- Starting Chemicals: These are the fundamental building blocks used to create the bisoprolol molecule. They must be of exceptionally high purity to ensure the final product meets quality standards.

- Solvents: These liquids act as mediums for the chemical reactions to take place. They are chosen for their ability to dissolve the starting chemicals and facilitate the reactions without interfering with the final product.

- Catalysts: These substances accelerate the rate of the chemical reactions without being consumed themselves. They are essential for efficient production.

All raw materials undergo rigorous testing to confirm they meet the required specifications before being used in the production process.

2. Synthesis:

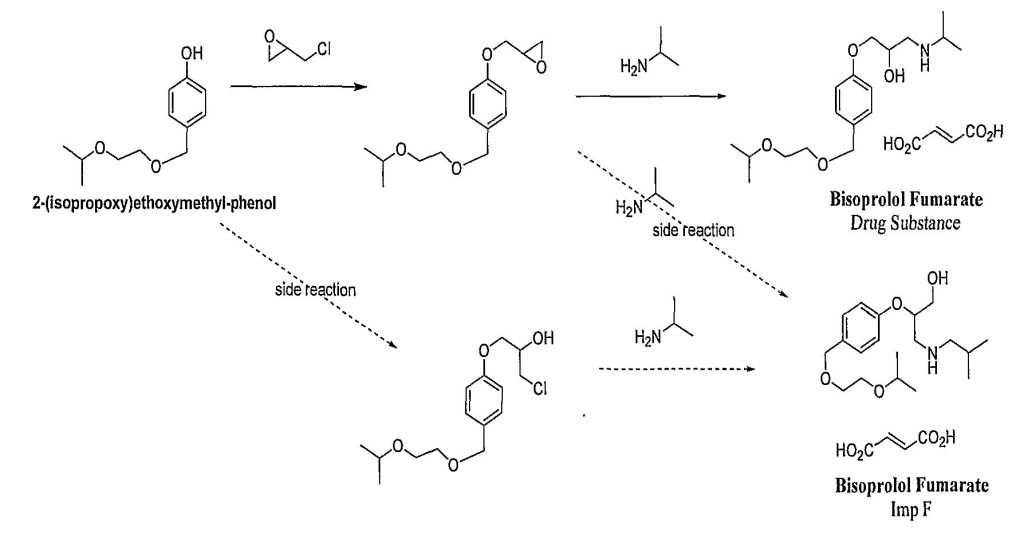

The synthesis stage is the heart of bisoprolol fumarate production. It involves a series of controlled chemical reactions that meticulously transform the starting chemicals into the desired bisoprolol molecule. The specific reaction sequence and conditions will depend on the chosen synthesis method. Here’s a general overview of the potential steps involved:

- Reaction Initiation: The starting chemicals are introduced into a reactor vessel along with a solvent and a catalyst. Specific conditions like temperature, pressure, and pH are established to initiate the desired reactions.

- Reaction Sequence: A series of chemical transformations take place, often involving functional group modifications and bond formations. These reactions may require additional reagents or adjustments to reaction conditions to ensure efficient conversion.

- Intermediate Product Formation: During the reaction sequence, one or more intermediate products might be formed. These are temporary molecules that ultimately lead to the final bisoprolol molecule.

- Final Product Formation: The final reaction step leads to the formation of the bisoprolol molecule. This may involve isolation and purification of the desired product from the reaction mixture.

Different synthesis methods may utilize variations in these steps, such as using protecting groups for specific functionalities or employing alternative catalysts to optimize reaction efficiency. Regardless of the chosen method, strict control over these reactions is crucial for obtaining a high yield of pure bisoprolol.

3. Equipment and Technology:

Modern pharmaceutical manufacturing heavily relies on sophisticated equipment to ensure consistent and high-quality production. Reactors, large vessels equipped with temperature and pressure controls, are used to conduct the chemical reactions. Filtration systems separate the desired bisoprolol intermediate or final product from unwanted materials. Purification units further refine the product by removing any impurities. Automation plays a crucial role in operating this equipment, minimizing human error, and ensuring consistent product quality across batches.

4. Quality Control:

Maintaining the highest quality standards is paramount throughout the production process. Rigorous quality control measures are implemented at every stage. Samples are extracted from the reaction mixture or isolated product at specific points and subjected to rigorous testing using advanced analytical techniques. These tests measure the purity of the bisoprolol, its potency (active ingredient concentration), and the presence of any potential contaminants or impurities. Only batches that meet all pre-defined quality criteria are released for further processing into medications.

5. Packaging and Storage:

Once the bisoprolol fumarate API meets all quality control specifications, it is carefully packaged in appropriate containers to maintain its stability and prevent degradation during transportation and storage. These containers may be designed to protect the API from moisture, light, or other environmental factors that could compromise its quality. The API is then stored under controlled temperature and humidity conditions until it is shipped to pharmaceutical companies for formulation into final medication products.

6. Challenges and Solutions

Despite advancements, challenges can arise during bisoprolol fumarate production. These may include:

- Maintaining consistent quality: Ensuring batch-to-batch consistency requires meticulous process control and robust quality control measures.

- Scalability: As demand for bisoprolol-based medications grows, manufacturers need to scale up production while maintaining product quality and consistency. This necessitates continuous improvement in production processes and equipment.

- Environmental impact: Pharmaceutical manufacturing can have an environmental impact. Manufacturers are increasingly adopting sustainable practices to minimize waste and resource consumption.

Solutions:

- Continuous process improvement: Implementing methodologies like Six Sigma can help optimize production processes, minimize errors, and ensure consistent quality.

- Advanced technology: Utilizing advanced technologies like continuous manufacturing can improve efficiency and scalability.

- Green chemistry principles: Employing green chemistry principles in the production process can minimize waste and environmental impact.

Conclusion

Bisoprolol fumarate stands as a vital API in the fight against cardiovascular diseases. Its ability to manage high blood pressure, angina, and heart failure makes it a cornerstone of modern medical therapy. Understanding the role of bisoprolol API manufacturers, the intricate production process, and the challenges encountered, sheds light on the complex journey this medication takes before reaching patients. As research continues, bisoprolol fumarate may find even wider applications in the future, solidifying its place as a key player in cardiovascular care.

If you are looking for a reliable manufacturer of bisoprolol fumarate APIs for business cooperation, Qingmu is a leading pharmaceutical company that can provide a variety of different types of pharma APIs to meet your needs.